For a mechanical packaging process, a wrapping material is guided around a product and the wrapping material is unwound onto the product. Ring or shuttle systems are used to guide the roll of material around the product, moving on a predetermined path.

These systems can only be used to a limited extent due to the specified tracks. Some tasks can only be fulfilled with great effort or not at all.

Based on this state of the art, we have made it our task to develop a system which is capable of guiding a roll of wrapping material on a flexible path (FlexLine) around products.

As a result we developed our FlexLine system "LineStrech-One".

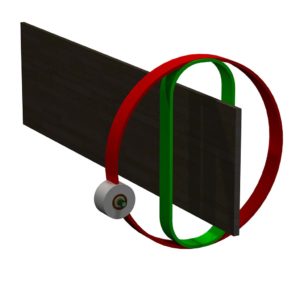

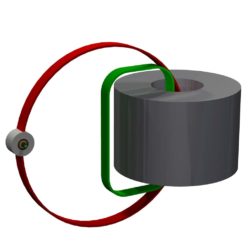

Principle

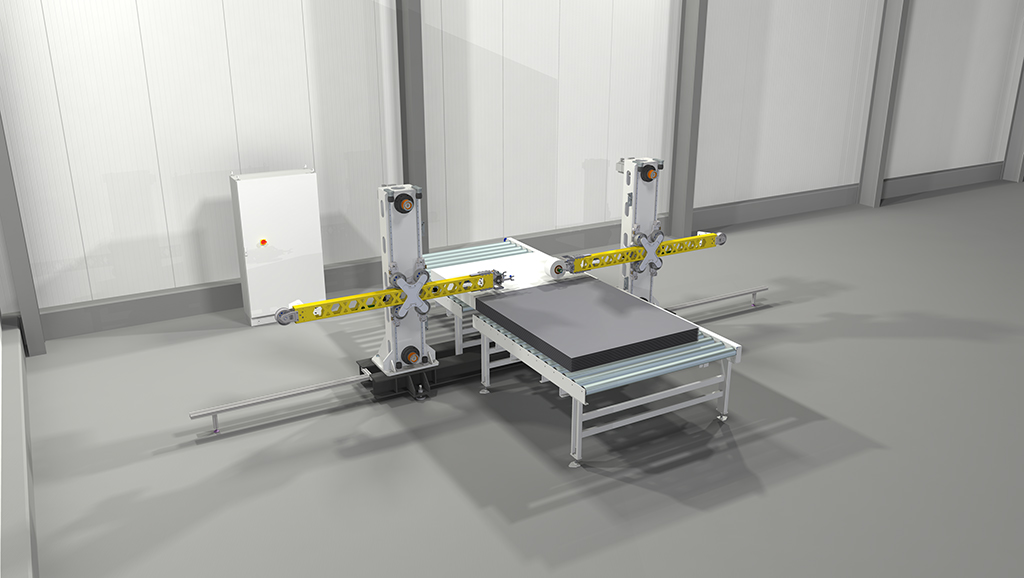

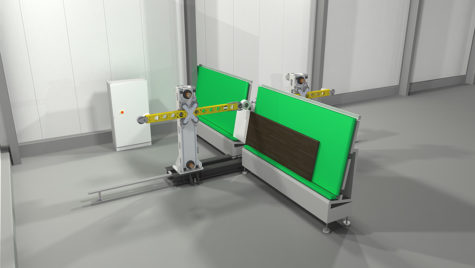

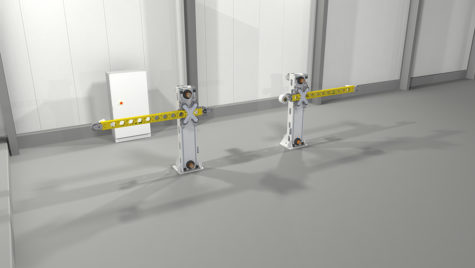

Two handling systems, consisting of a horizontally and vertically moving axis, face each other. A gripping system is mounted at each end of one of the axes, which can hold the roll of wrapping material. During the wrapping process, the roll of wrapping material is transferred from one handling system to the other. The handling systems can move freely in space on their axes.

Thus it is possible to guide the roll of wrapping material always on the optimal way around a product or also through a product.

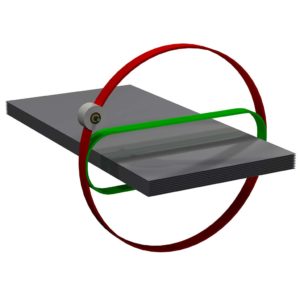

Red orbit = Ring system (CircleLine)

Green orbit = LineStretch-One (FlexLine)

Grey = Product

FlexLine technology enables applications that are not possible with a ring system (CircleLine).

Depending on the arrangement of the two movement systems and the choice of suitable conveying and guidance techniques, a wide variety of applications can be realized: