This horizontal stretch wrapper fixes your product and protects the surface with stretch film in which the long goods are wrapped or bundled.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

Our stretch wrappers are used to pick, fix and protect your long goods. Based on our many years of know-how, we offer you a need-based wrapping machine including programs to wrap your product individually.

Whether bundled or completely wrapped, whether manual, semi-automatic or automatic, we offer you an efficient and economical solution for your application.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

This manually operated Circle-Line wrapping machine is universally used for long products. The ring size or angle head size is determined from your product cross-sections. It is a simple basic model where the machine operator handles the product and film handling independently.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

It is a manually operated Circle-Line wrapping machine, which is used for your long goods. The adjustable parameters simplify the wrapping process. This wrapping machine, designed for industrial use, optimizes the efficiency of your wrapping process and can be equipped with options suitable for the application.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

This is a semi-automatic operating Circle-Line wrapping machine, which is used for your long goods. The different operating programs allow the multifunctional use of this wrapping machine. Due to the manual or semi-automatic product processing, you can optimally use this wrapping machine for your most different products.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

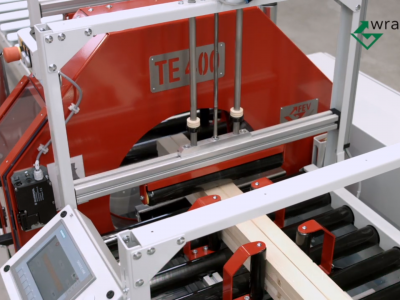

It is a fully automatic Circle-Line wrapping machine, which is used for your long goods. The film wrapping machine distinguishes in the different processing programs between wrapping, bundling and wrapping bundles. Sensors automatically detect your product and start the fully automatic wrapping process. Even in its standard version, the machine control allows the wrapping machine to be integrated into automated lines.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

This is a fully automatic process that was explicitly tailored to one customer. The wrapping line works with height-adjustable conveyor units to transport the products to and from the wrapping units in a synchronized manner. Two wrapping units are used to wrap the products. The wrapping heads are self-propelled and, in addition to the stretch film, dispense a foam edge protection.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

The fully automatic line wraps the products into a commission. The conveyor system behind the wrapping unit lowers after the product has been wrapped and places the product on a second conveyor unit. This conveys the products crosswise and buffers them until they are removed.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

The special feature of this wrapping machine is the angled conveyor unit. This allows the operator to pick the products. As soon as the operator is finished, he starts the fully automatic wrapping process by pushing a button.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

This wrapping machine is a fully automatic process. It is equipped with a nonwoven curtain system. In the infeed area, the product contours are measured and the required fleece width is selected as a result. The product to be wrapped is conveyed through the curtain and the wrapping machine fixes the nonwoven to the product and stretches it. In order to achieve maximum throughput, the wrapping head is equipped with a double film roll system.

The target application of the wrapping machine for long goods is the fixing and protection of products. The degree of automation of the machine solution depends individually on your application. The wrapping ring size is based on the size of your products to be wrapped. This application offers you insight into the packaging variety of long goods such as aluminum profiles, stainless steel tubes, baseboards or similar. When processing long goods, suitable conveyor technology is recommended in front of and behind the wrapping machine, which we as a packaging machine manufacturer naturally also produce to suit your product and your area of application. This also includes machine components that safely guide and fix your products during the wrapping process.

If your product dimensions are very large, please also refer to the application area of large packages .

If you did not find your product in this application area, please contact us. As a manufacturer of packaging machines we distinguish ourselves for customer-oriented project planning.

Our employees will be glad to help you any time: +49 5731 860 01–0

The following brochures provide information on our standard wrapping machines. We will be happy to discuss any special solutions required for your individual application in a joint meeting. Contact us at any time.